Our Project Journey

TU (Hmawbi)

Electrical Power Engineering

Project Showcasing

Light Sensor

A Light Sensor Module is an electronic device that detects the

intensity of light in the surrounding environment. It converts light

energy into an electrical signal that can be read by a

microcontroller (like Arduino or Raspberry Pi). In greenhouse

projects, this sensor helps monitor sunlight levels to maintain

optimal lighting conditions for plant growth. When sunlight

decreases (for example, in the evening or during cloudy weather),

the sensor detects the drop in light intensity. The system (e.g.,

Arduino) then automatically activates artificial lights to maintain

the proper brightness level for plant photosynthesis.

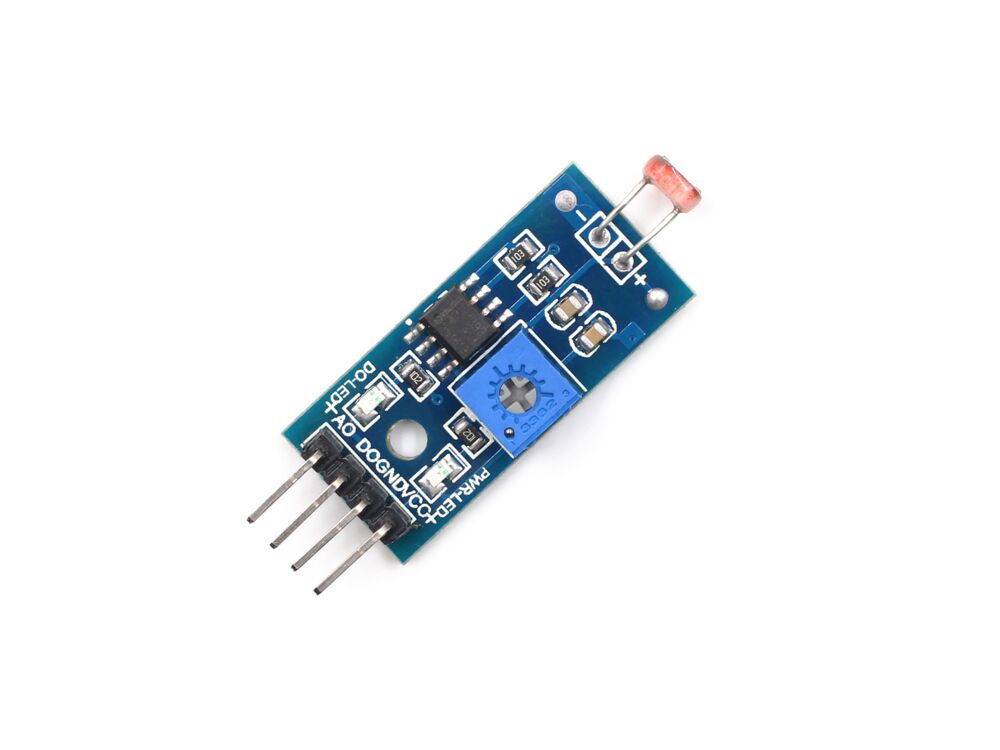

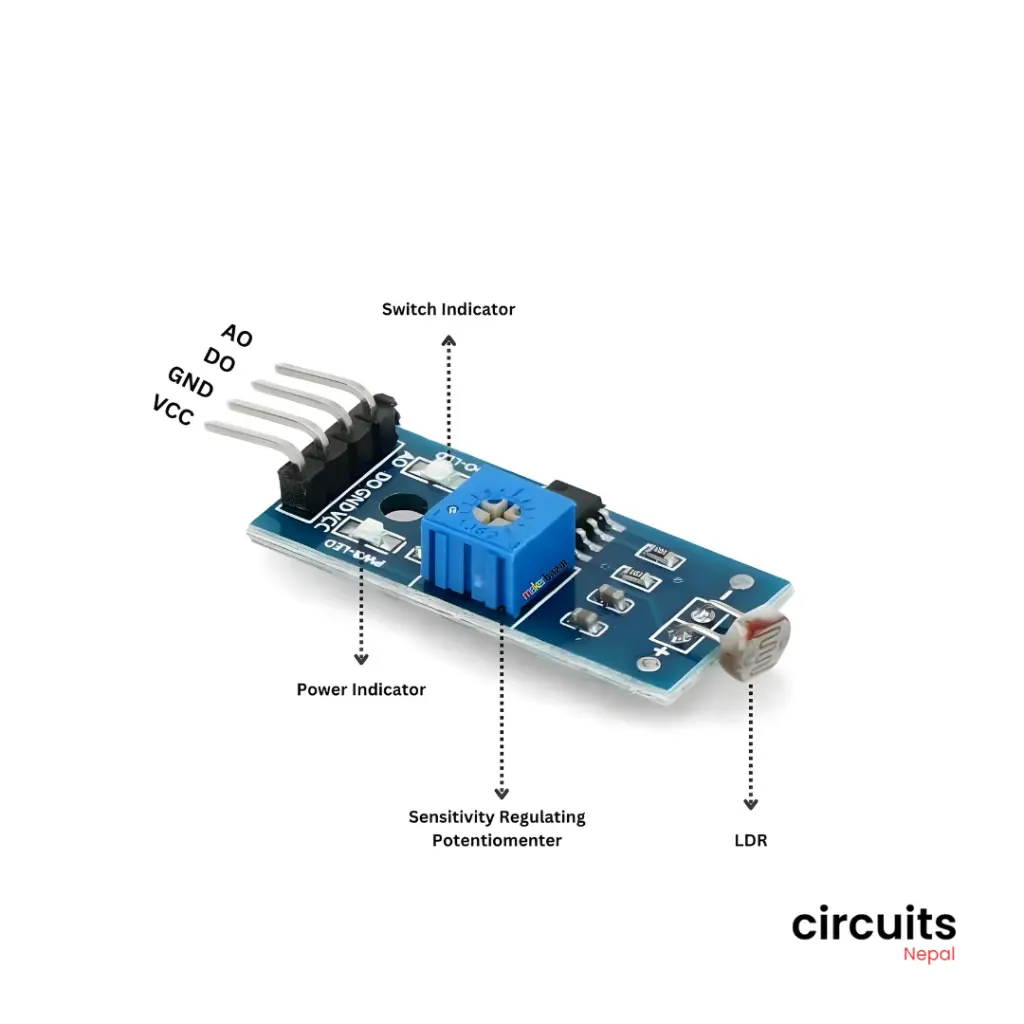

Light Sensor Module with four distinct connection pins, which are

standard for many basic electronic sensor components. The VCC pin is

for the power supply voltage (often 5V or 3.3V), while GDN (likely

labeled as GND on the actual module) represents the Ground

connection, completing the power circuit. The output pins provide

data: DO stands for Digital Output, which typically provides a

simple HIGH or LOW signal based on a set threshold of light

intensity, making it suitable for simple on/off control like a basic

light-activated switch. Finally, AO stands for Analog Output, which

provides a variable voltage proportional to the actual measured

light intensity, offering a more nuanced reading for applications

requiring continuous light measurement.

Main Components of Light Sensor Classification of main components in the light sensor include the following types of components:

1. Photoresistor (LDR – Light Dependent Resistor) 2. Resistor (Fixed Resistor) 3. Comparator IC (e.g., LM393) 4. Potentiometer (Variable Resistor) 5. Power Indicator LED and Output LED 6. Output Pins

Uses :

In a greenhouse, plants need an appropriate amount of sunlight for healthy growth. The Light Sensor Module is used to :

1. Monitor Light Intensity: Detect whether plants are receiving sufficient light. 2. Control Artificial Lighting: Automatically turn ON grow lights when natural sunlight is low and turn them OFF when sunlight is adequate. 3. Data Logging: Record daily light levels to analyze growth conditions. 4. Energy Efficiency: Helps maintain ideal lighting using minimal electricity.

Advantages are followings :

1. Low Cost: Affordable and easily available for student and prototype projects. 2. Simple Operation: Easy to connect and use with microcontrollers. 3. Adjustable Sensitivity: Light threshold can be modified with the potentiometer. 4. Low Power Consumption: Suitable for continuous monitoring in energy-saving greenhouse systems.

It also has Disadvantages :

1. Limited Accuracy: Not as precise as advanced light sensors like photodiodes or lux meters. 2. Affected by Environmental Factors: Temperature or dust on the sensor may slightly affect readings. 3. Limited Range: Can detect only a certain range of visible light, not the full light spectrum used by plants.

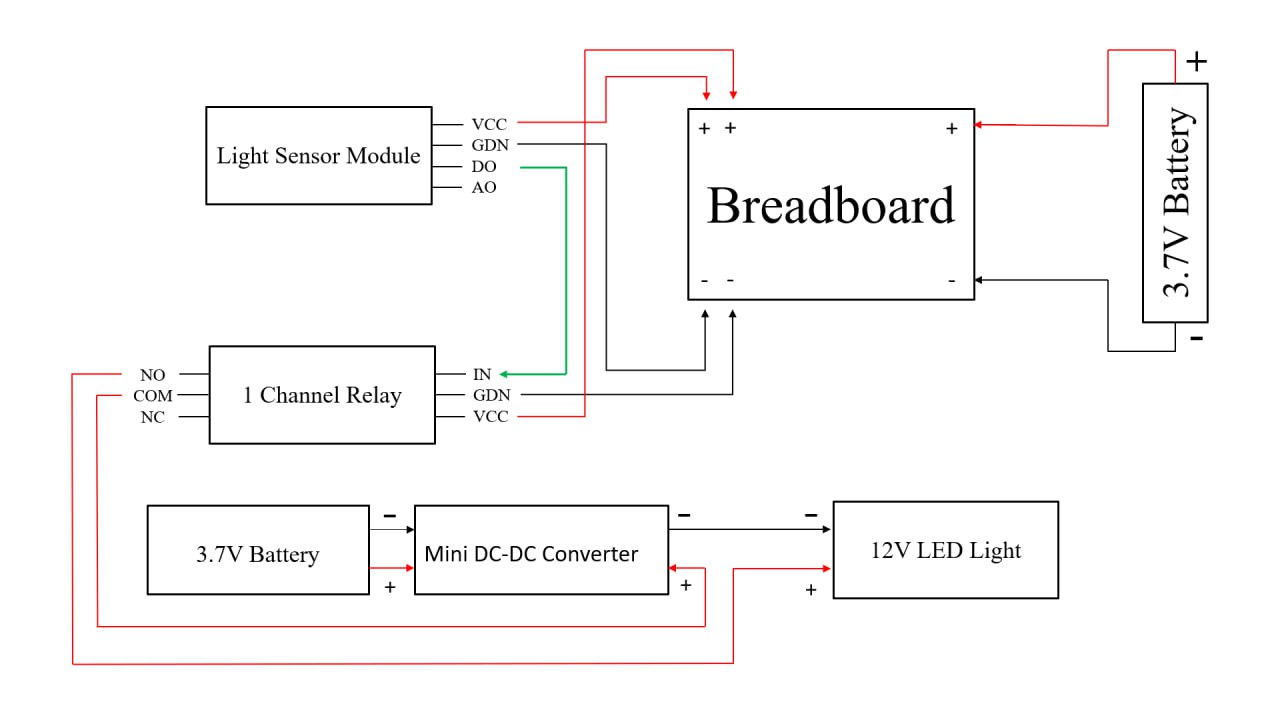

Fig : Circuit Diagram of Smart Lighting System

Smart Lighting System

A smart lighting system can be defined as an automated setup where a light sensor module is used to intelligently control a light source, specifically a 12V blue LED light. The system's "smart" functionality comes from its ability to automatically turn the light on or off based on the ambient light level detected by the sensor. This sensor's digital output (DO) triggers a 1-Channel Relay, which acts as a switch for the higher-voltage LED circuit. The circuit is designed to be self-contained and efficient, utilizing a 3.7V battery for the control electronics and a second 3.7V battery combined with a Mini DC-DC Converter to efficiently boost the voltage to the required 12V for the blue LED, illustrating a basic form of automated, low-voltage control over a higher-voltage load.Construction of Smart Lighting System

1. A blue 12V LED light is automatically controlled by a light sensor module and a 1-channel relay. 2. The entire system is powered by a 3.7V battery connected to the breadboard. 3. The light sensor's output (DO) is wired to the relay's input (IN), enabling the relay to switch its state—likely to turn the light on when it's dark and off when it's bright. 4. A separate 3.7V battery supplies power for the LED circuit, which passes through a mini DC-DC converter to boost the voltage to the necessary 12V for the blue LED light, with the relay's Normally Open (NO) and Common (COM) terminals acting as the switch to complete this high-power circuit.